Electrical, Power, and Energy Capabilities

Enterprise Ventures Corporation (EVC) is the technology transition affiliate of Concurrent Technologies

Corporation (CTC). EVC transfers advanced technologies developed by CTC and others to the industrial base,

delivering high-quality products and services to clients across industries.

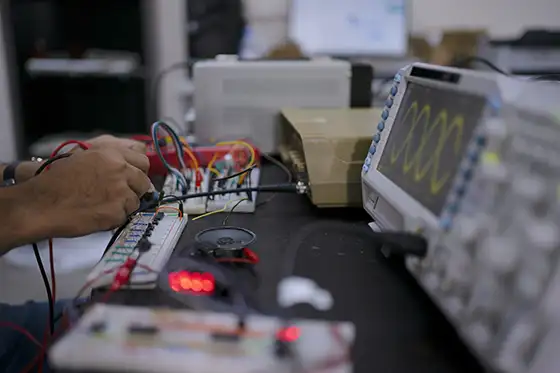

We possess extensive experience in selecting, integrating, testing, and troubleshooting a wide range

of hardware components, including electric motors, variable frequency drives, pressure transducers,

thermocouples, contactors, relays, voltage transducers, current transformers, motorized valves, limit switches,

level sensors, and more.

Core Capabilities

- Design of complex system integrations involving fuel cells, hybrid generator systems, energy storage systems, power electronics, and control systems.

- Reverse engineering for system troubleshooting and repair.

- Test plan development and execution.

- Testing of microgrid power systems, including utility inter-tie,

- renewable energy sources, and multiple load outputs.

- Development and programming of control systems using

- Siemens S7-1500 PLC (approx. 200 I/O points).

- Development and programming of autonomous control systems

- using Siemens S7-1200 PLC (100+ I/O points).

- Design and construction of a diesel/battery hybrid aircraft tow vehicle.

- Creation of schematics, 3D models, and conceptual design layouts.

- Experience in aerospace electrical systems design, test, installation, certification, production, and

- maintenance support.

- Experience in wire harness design and assembly.

Tools and Software Proficiency

- AutoCAD (Releases 14, 2000, 2002, LT, 2009 Electrical, 2010)

- LabVIEW (Versions 7.1, 8.0, 8.1, 10.0)

- Siemens Step 7 (Versions V11, V12, V15)

- DirectSoft 5

- PowerVision Configuration Studio 2.8

Additional Experience

- Contractor selection and oversight for on-site project execution.

- Technical oversight and subcontractor supervision during project build phases.

- Vendor coordination and procurement of electrical/mechanical components.

- Specification of panelboards, main distribution switchboards, and motor control centers.

- Familiarity with relevant sections of the 2011 National Electric Code, including photovoltaics, wire and conduit sizing, and other key areas of electrical design/build.

- Development of contractor statements of work (SOWs).

- Electrical schematic design for custom control cabinet fabrication.

- Creation of single-line power and communication diagrams.

- Design and fabrication of military-grade cable harnesses.

- Experience in maintaining engineering data package configuration management (CM) and Engineering Change Process (ECP).

- Experience in electro-mechanical prototype development, manufacture, and test support.

- Limited experience in simple Fiber Optic Assemblies.

- Obsolescence management and replacement of outdated parts/equipment.

- Testing and troubleshooting of Winch Control Assembly hardware used in the CSTRS system.

- Proficiency with the Navy’s NextGen Interactive Electronic Technical Manual (IETM) for the MH-60S aircraft.

- Development of drawings and work instructions for specialized tooling and shop aids.

- Certified IPC Specialist per IPC J-STD-001 (Requirements for Soldered Electrical and Electronic Assemblies).