Production Services

Helping government, commercial business, and entrepreneur clients take their research, technologies, and products to market

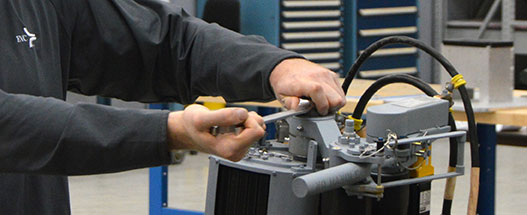

What makes EVC Production unique? It’s our ability to tap into the expertise from all EVC divisions. We leverage the engineering design and development capabilities of our partners and our parent company, Concurrent Technologies Corporation (CTC). Using our robust supply chain, we manufacture, assemble, and test to customer drawings and specifications. And most importantly, we afford our customer with remarkable value in meeting production needs!

CALL OR EMAIL:

DOMINIC STEVENS

MANUFACTURING PROJECT MANAGER

EVC Production Services Capabilities

- Full scale manufacturing, assembly, and testing of highly-specialized and complex systems, as well as smaller fabricated parts and tools, for government and commercial customers

- Full complement of product lifecycle management activities:

- Pre-production manufacturing engineering

- Production services

- Sustainment activities that encompass repair, sparing, and training

- Assembly of complex riveted structures

- Production of electronics assembly, integration, and testing

- Fabrication of custom, task-specific tools

- Manufacturing and industrial engineering

- Specialization in prototyping and low rate initial production (LRIP)

- 20,000+ square feet of manufacturing, assembly, test support, and secure inventory floor space, with up to 200,000 square feet available

Why Use EVC Production?

- Access to EVC’s diverse consulting services, such as: Quality, Safety and Occupational Health, Strategic Planning and Process Improvement, and IT Software Support

- A robust, qualified supply chain

- Our culture of quality, continuous improvement, and operating excellence

- Proven best business practices

- Detailed focus on all aspects of production, manufacturing, and repair; we meet and exceed industry standards and customer expectations

- FAA licensed maintenance technicians capable of expert aviation systems fault analysis, testing, and repair

- Certified to the AS9100 standard (includes all ISO 9001 quality management system [QMS] requirements)

- Track record of 100% on-time delivery